Edge Inspection

EDGE

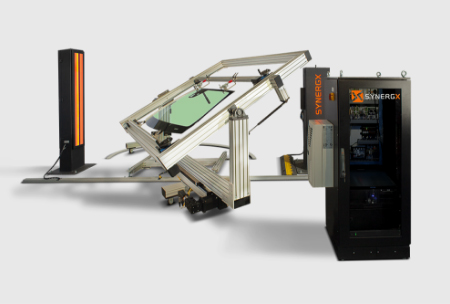

The EDGE is a family of products providing high quality glass processors with an integrated inline flat glass surface and grinding edge inspection solution meeting the high level required by the OEM Automotive and appliance glass industries

Benefits

Improves product quality to meet glass manufacturer’s increasingly high expectations

Reduces production costs through productivity improvement

Captures key data for continuous process improvement

Convenient footprint and flexible interface allow easy integration into existing production or greenfield project

Features

Improve the quality of your products. Improve your manufacturing processes and productivity.

Detects

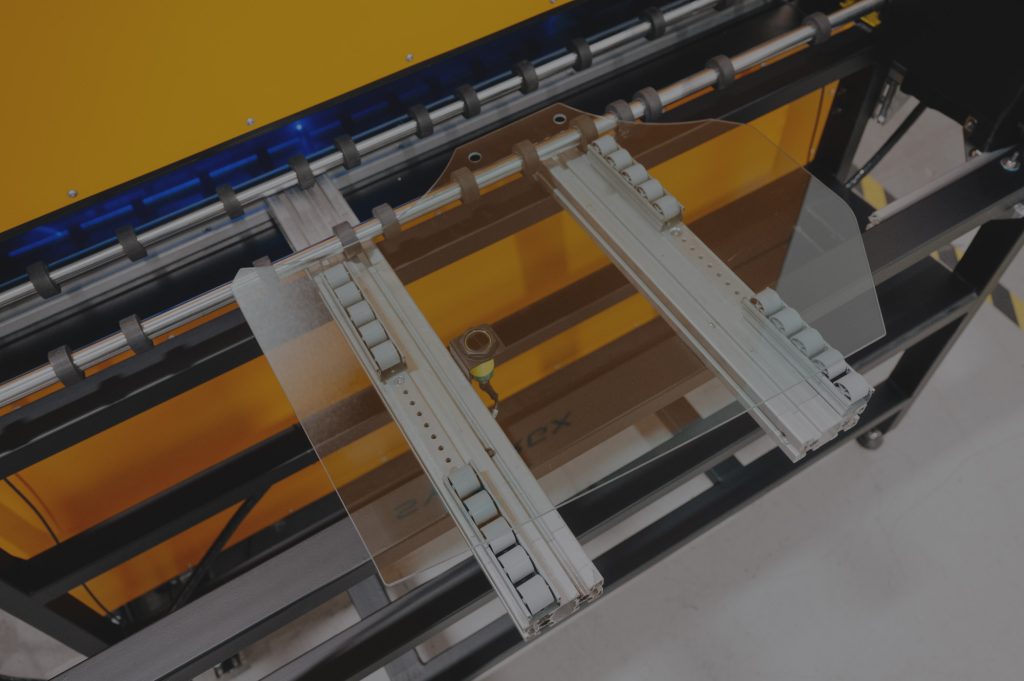

Detection of shiners and edge chips vents, scratches, inclusions, bubbles not visible from the surface

Speed

Line speeds up to 60 m/min

Cycle time

Industry-leading cycle time: 4 seconds

Glass transparency

Dark tint to clear glass inspection (5.6% to 92% transmittance)

The EDGE inspection system is fully integrated to your manufacturing process and is based on the Synergx GI platform

Contact our glass experts to learn about the full comparison between the systems

Send us a request for information and a specialist in your market will contact you.

Other popular products in the glass industry

Welcome to a new era of precision.

Case Study

AGNORA detects architectural glass defects faster thanks to SYNERGX

Discover how SYNERGX contributes to fulfilling AGNORA’s mission to produce impeccable architectural glass!